Enhancing Safety of Brake System Components

Partner with us to protect your NEV brake architecture with precision, engineered solutions that ensure cleanliness, sealing integrity, and mechanical protection — from hydraulic lines to electronic parking brake systems.

Fluid Port

& Connector Sealing

Electronic Interface & LV Connector Shielding

Vacuum & Sensor Port Dust Coverage

Cleanroom-Ready

Protection

Protecting Reliability in Brake System Components

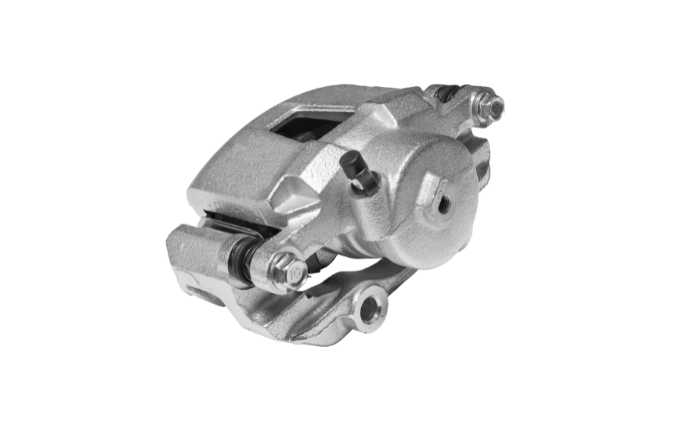

In New Energy Vehicles (NEVs), brake systems combine hydraulic precision with electronic control to ensure safe, responsive performance. From master cylinders to electronic parking brakes, each component must remain clean, sealed, and protected throughout production and assembly.

Brake system protection against contamination, damage, and fluid leakage across all components.

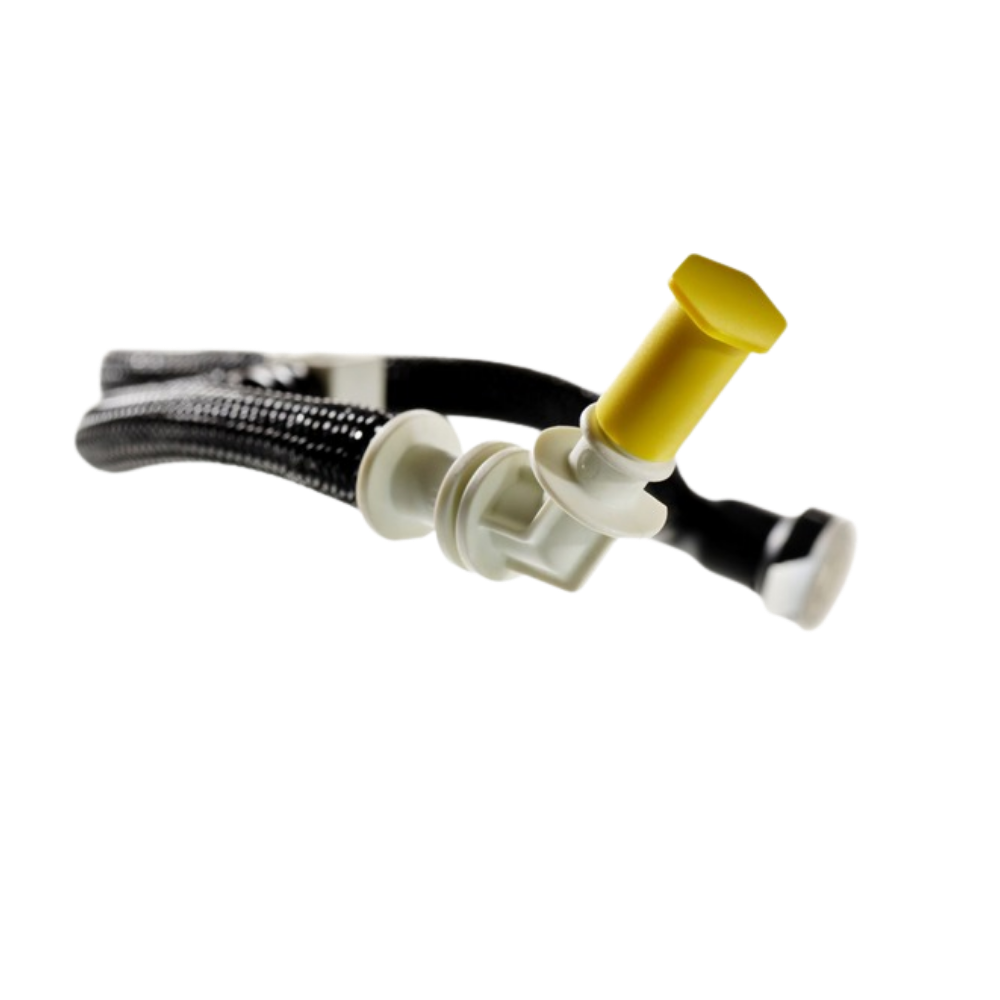

Sealing Fluid Interfaces

Durable caps and plugs secure fluid inlets, outlets, hose ends, and brake lines to prevent leakage and contamination in master cylinders, hoses, and ABS units – ensuring system readiness and cleanliness.

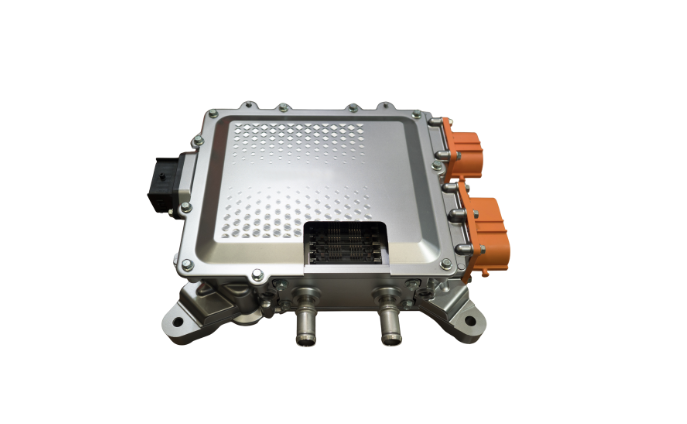

Safeguarding Electronic Connections

Sensitive connectors on ABS modules and EPB actuators are shielded from dust, impact, and electrostatic discharge, minimizing the risk of damage during handling and logistics.

Protecting Vacuum & Sensor Ports

Brake boosters and control units are covered to prevent mechanical damage and debris intrusion, preserving vacuum integrity and ensuring consistent performance.

Manufactured for Cleanroom Compliance

Our production processes meet ISO 14644 standards and follow VDA 19.1 guidelines, supporting technical cleanliness for critical brake components in high-performance NEV platforms.

Full service. Always.

Complete protection and services at every stage

We Are Your Partner for Efficient and Reliable Supply. This is our offering and our ambition is to be your preferred full-service protection solution partner.

Integrated Packaging & Supply Chain Solutions

We offer ESD packaging, custom labeling, and EDI integration for efficient, high-quality support.

Our reusable KLT containers and customizable packaging boost supply chain efficiency and sustainability.

Quality Management and PPAP

DBI is certified to ISO 9001, IATF 16949, and ISO 14001, ensuring compliance and quality.

We use PPAP and our APQP database to support validated, transparent development.

Reliable ESD Safety Protection

Protecting sensitive automotive components from electrostatic discharge during handling, transport & storage.

Our solutions ensure compliance with industry standards and safeguard the reliability of high-voltage and electronic systems.

Advanced Cleanroom Solutions

Ensuring optimal protection and cleanliness for sensitive automotive components.

Our advanced cleanroom solutions maintain controlled environments to safeguard the integrity of high-precision systems.

Explore Our Protection Solutions

Do you need advice?

Reach out to our expert for more information.

Please submit the form to contact us.

.png)

.png)